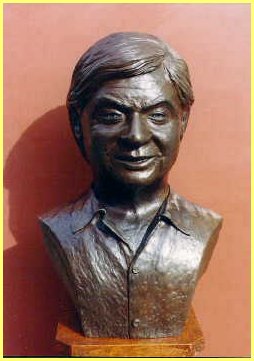

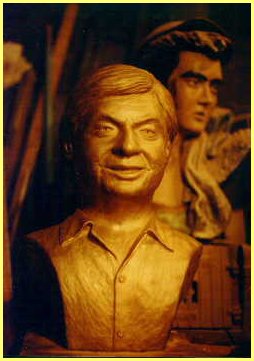

To create a bronze work of art many complex steps are involved.

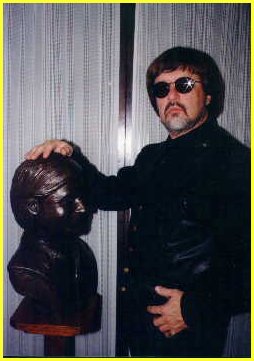

When artist David John Mega received the commission to sculpt

the bust of Dr. Jose Camargo, he photographed each step.

The following is in essence a documentary of the creative

process from inception to completion of the art work, and presents

visual images along with text explaining the procedure.

BRONZE CASTING PROCEDURE

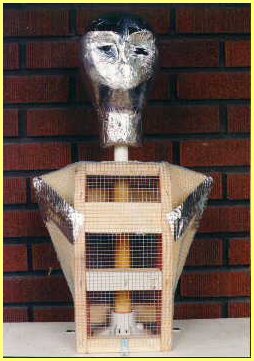

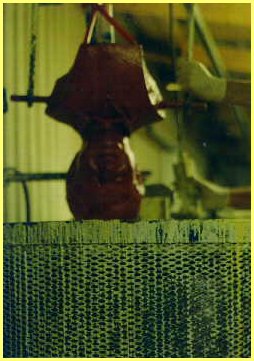

Armature Construction

The basic construction of the armature is created with wood and foam.

Wire mesh and metal foil are added to insure that clay bonds well to the surface.

Then the armature is covered with Non-Sulphurated Plasteline.

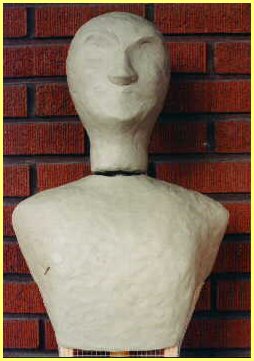

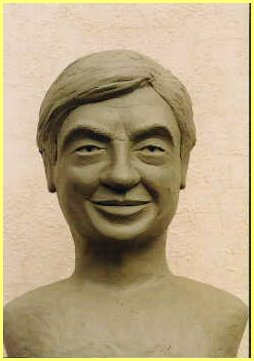

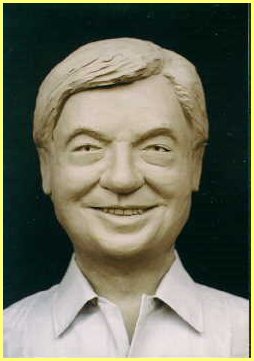

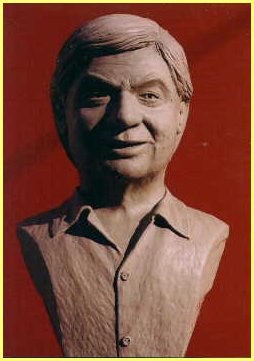

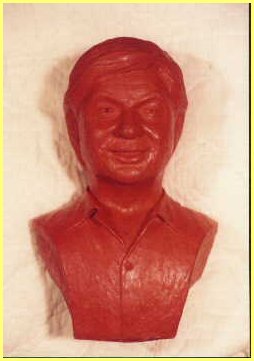

Model Development

Various approaches are tested to establish the style of the piece

and to achieve the likeness and character of the subject.

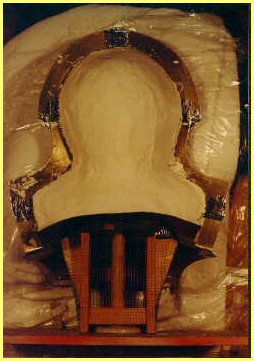

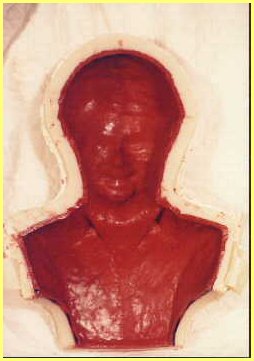

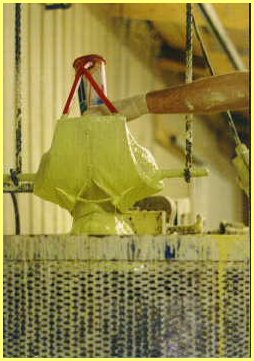

Mold Making (front)

The model is divided into front and back halves with thin metal shims, and a clay dam is built to contain mold material. Several layers of flexible urethane rubber are applied to the model surface to a uniform thickness. Then a plaster ” Mother Mold ” is used to hold the flexible urethane mold form in place.

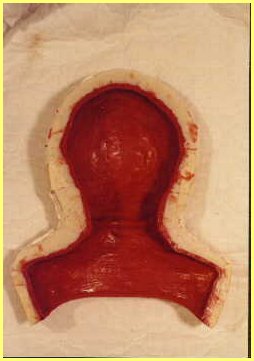

Mold Making (back)

The process used in making the front mold

is then repeated for the back half.

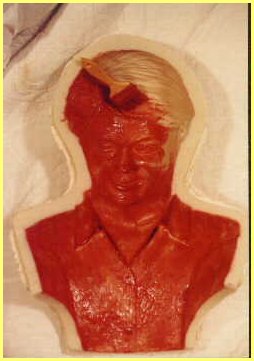

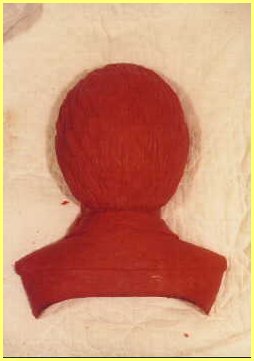

Building Wax Positive

Molten wax is applied to the inside of the urethane mold with a natural bristle brush.

Many layers of wax are slowly built to assure uniform thickness of approximately ¼ inch, and the back section is built to same uniform thickness. Wax is released from mold after sufficient cure time to prevent warping. Front and back sections are joined together with molten wax and joint seams are “chased” to appear seamless.

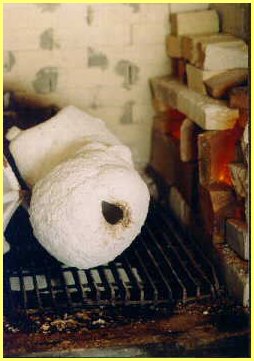

Ceramic Molding

Sprue and vent systems of wax are attached to the wax model by which the heated wax will later flow from the mold and the molten bronze will enter, then the dipping process begins. The wax model is coated with a refractory ceramic material then coated with sand. The refractory-sand process is repeated several times over a period of days under constant temperature and humidity requirements until a desired thickness is reached. After the shell is thoroughly cured the piece is placed in a kiln for hours to remove any moisture and eliminate the wax creating a positive void in which will be poured the molten bronze.

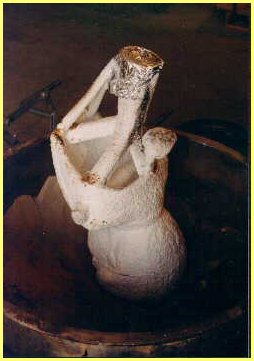

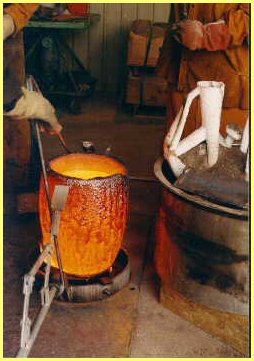

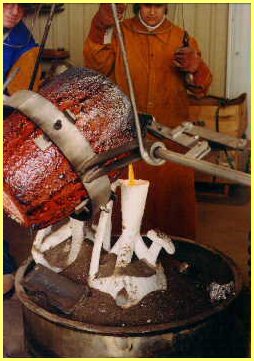

Casting

The heated ceramic shell is placed into a steel container and held in place with sand. Molten bronze of approximately 2,200 F is prepared for the pour, and the molten bronze is poured in a team effort. The cast piece remains in sand allowing the bronze to solidify and the molecules to align in a proper matrix.

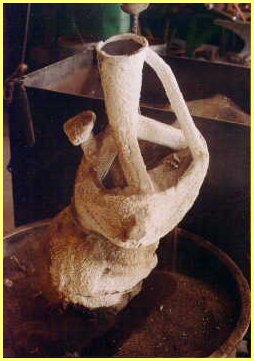

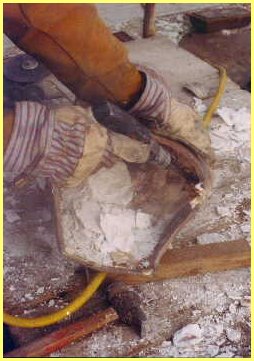

Shell Removal

The ceramic shell is carefully removed so as not to damage the bronze. As much shell is removed by hand as possible, and air tools are employed in the interior areas. The sprue systems and vents are removed with carbon abrasive cut-off wheels.

Bead Blasting

In order to remove the remaining shell, 100 mesh silica under 100 lb. air pressure is used to blast the bronze.

Metal Chasing

All final remains of the sprue feeder system are removed. TIG welding utilizing bronze rods eliminate any imperfections. Separately cast pieces are attached with the use of the TIG welder and bronze rod.

The metal is then “chased”… ground, filed, and sanded.

After chasing process the entire sculpture is again bead blasted to create a uniform surface.

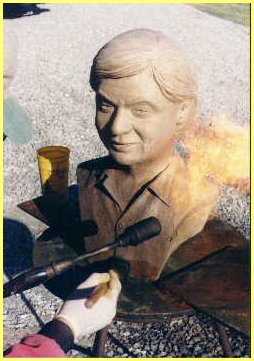

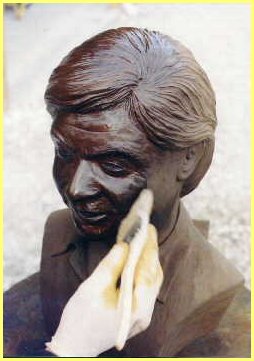

Patina Process